MOULD MAKING

FROM DELICATE DETAILS TO COMPLEX STRUCTURES – WE GIVE PERFECT SHAPE TO YOUR IDEAS.

We produce tools for you for prototypes, pilot series and series production, as well as multi-component tools, blowing tools and gas assisted injection moulding tools. In our state-of-the-art and fully equipped mould making facility, we meet your needs for quick pre-series tools, classic aluminium prototype moulds and hardened formed steel inserts for plastic injection moulding.

Prototype Tools

Quantities of up to 1000 in aluminium or steel.

Blow Moulding Tools

Up to a size of 3m x 2.5m and a maximum weight of 20 tons

Gas internal pressure tools

Complex hollow structures with high dimensional accuracy

Multi-component tools

Reduction of assembly steps through direct integration

MuCell®-Technology

Lightweight, cost-effective plastic components through microcellular foam injection molding

Prototype Tools

Quantities of up to 1000 in aluminium or steel.

Blow Moulding Tools

Up to a size of 3m x 2.5m and a maximum weight of 20 tons

Gas internal pressure tools

Complex hollow structures with high dimensional accuracy

Multi-component tools

Reduction of assembly steps through direct integration

MuCell®-Technology

Lightweight, cost-effective plastic components through microcellular foam injection molding

Our mould making services

PERFECTION IN EVERY CONTOUR

Every employee who works to produce our wide variety of tools is a professional – offering the very highest quality and expertise, from consulting to implementation.

TECHNICAL CONSULTING

Our expertise for your success.

We are always here to advise and support you with our expertise and specialist knowledge in mould making, materials, design and production processes. Choosing the right material is just as important as complying with specified standards and optimising the production processes in order to ensure cost-effective and sustainable production and the quality of your products.

Photo: Landesmesse Stuttgart GmbH

PROTOTYPE TOOLS

Your design in perfect shape.

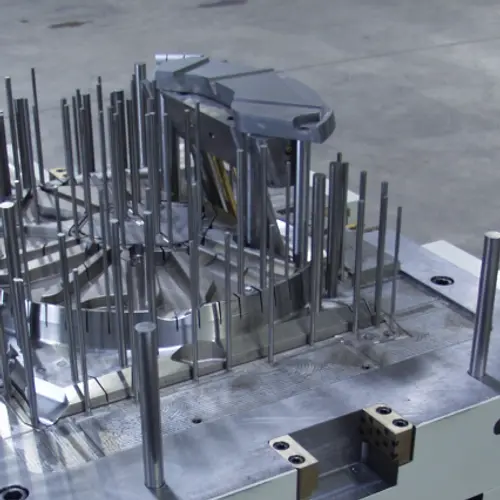

Prototypes lay the foundations for success in series production. We provide quick and straightforward production of your prototype tools with guaranteed quantities of up to 1000 in aluminium or steel.

We use separate sections to manually remove undercuts and difficult component geometries from moulds. Our master mould concept reduces the purchase costs for tools and therefore also reduces costs for our customers.

Aluminium prototype tool – quickly and reliably driving innovative developments.

SMALL-SERIES TOOLS

Limited quantities – limitless possibilities.

We can produce pre-series injection moulding tools in next to no time to meet your requirements for initial samples or small series made of various original materials. We can organise and supply plastic materials.

The range extends from simple aluminium tools with manual unloading to fully automatic steel/aluminium tools with hot runner technology.

Steel tool in our injection moulding technology centre.

BLOW MOULDING TOOLS

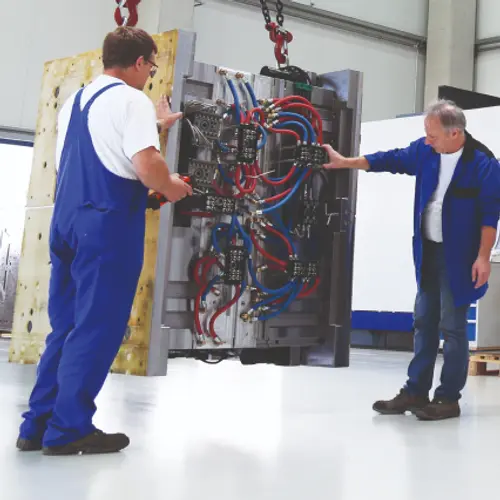

Air and form – blow moulding tools that bring your ideas to life.

Our company specialises in the manufacture of aluminium blow moulding tools. We can produce tools for our customers up to a size of 3 m x 2.5 m and a weight of 20 tonnes.

Our range of services includes prototypes and series-produced blow moulding tools for engineering plastic parts.

Dual suction blow moulding tool for corrugated tubing.

INJECTION MOULDING TECHNOLOGY CENTRE

Fusing together innovation and experience.

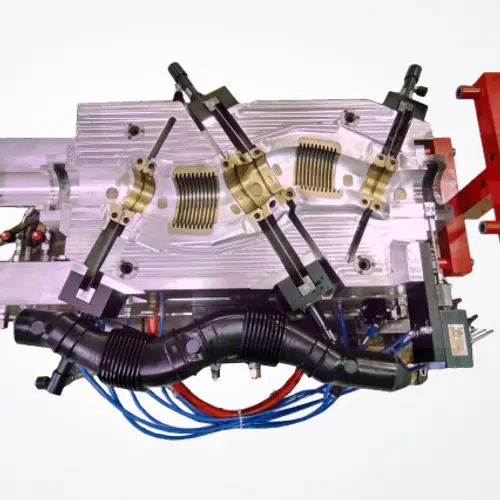

Our state-of-the-art injection moulding technology centre enables us to produce injection moulding parts weighing between 1 g and approx. 4 kg. The range of materials extends from simple polypropylene to engineering plastics such as PPS. We achieve locking forces of 900 KN to 20,000 KN with our varied machinery.

This is also where we make your prototype tools that need to be precise, quick and cost-effective, as well as small-series and series-produced tools.

Injection moulding technology centre – machinery.

FINISHING

The perfect finish for your products.

Our assembly departments complete the finishing work on prototype, pre-series and small-series parts, treat the surfaces, adjust them with various additional parts and finally assemble them into functioning modules.

We offer a broad range of different finishing and marking methods to give the components high-quality surface finishes as requested by our customers.

Handle with real wood trim and back injection moulding, arm rest with foaming and lamination.

FAQ - Mold making

Interesting facts about mold making

- 1. Interesting facts about mold making

Mold making is a central process in industrial manufacturing, enabling the production of precise molds and tools essential for mass production. Products made from plastic, aluminum, or metal are created using custom-made molds. Mold making plays a key role in industries such as automotive, medical technology, and consumer goods, ensuring high repeatability and consistent quality for identical components. Processes like injection molding produce precise parts tailored to specific requirements, ensuring efficient and cost-effective production.

- 2. Mold making and tool making: what is the difference?

Mold making and tool making are closely related but have different focuses. Mold making is centered on the production of molds used to manufacture parts, typically from plastic or metal. These molds are commonly used in the injection molding process where molten material is pressed into a mold to create identical products.

Tool making goes beyond mold production and encompasses a wider range of tools and fixtures used in various manufacturing processes, such as stamping or cutting tools. Tool making involves creating tools for the entire production process, extending beyond mold creation. It includes stamping tools, forming tools, or cutting devices needed for different manufacturing operations.

Both disciplines are essential for enabling production of precise and high-quality parts. While mold making primarily focuses on shaping, tool making develops the necessary tools to integrate these molds into production efficiently and cost-effectively.

Summary:

- Mold making: Production of molds, e.g., for injection molding.

- Tool making: Production of various tools for numerous manufacturing processes.

- 3. How does mold making work? The process from idea to production.

Mold making is a complex, multi-stage process closely linked to the design of the final product. The workflow includes:

Design and Planning: During the design and planning stages, MODELLTECHNIK supports its customers with comprehensive technical consulting. Using CAD software and simulation tools, our engineers assist in making the components tool-ready as early as the design phase.

This consulting-based component design optimizes mold design and minimizes later adjustments, making the production process significantly more efficient and cost-effective.

Material Selection: Depending on the component’s requirements, materials such as aluminum, steel, or plastic are chosen. Aluminum is lightweight and efficient for medium series, while steel is used for high production volumes due to its durability. MODELLTECHNIK primarily uses aluminum for prototype and small-series tools.

Mold Manufacturing: The molds are produced with the highest precision through processes like CNC milling or additive manufacturing. Modern technologies ensure that even the smallest details are perfectly implemented.

Testing and Adjustment: The dimensional accuracy and surface quality of the prototypes are checked and adjustments are made immediately to ensure functionality.

Production: Once the mold has passed all tests, production begins. The injection molding process enables the quick and precise manufacturing of identical components.

Mold making at MODELLTECHNIK is characterized by its innovation and the use of modern technologies, enabling fast and precise implementation.

- 4. What Material Is Used for Mold Making?

Choosing the right material is crucial in mold making, as it determines both production efficiency and mold durability. Depending on the project requirements and the final product, various materials are used:

Plastic in Mold Making

Plastics are often used for prototypes, small series, or simple molds. They are easy to work with and cost-effective, making them particularly attractive for short-term or flexible projects. Another advantage is that plastic molds can be produced quickly, significantly speeding up prototyping. However, they have a shorter lifespan and lower durability than metal molds, making them more suitable for less demanding applications. For projects that don’t require high mechanical or thermal resistance, plastic offers a good balance between cost and functionality.Aluminum in Mold Making

Aluminum is frequently used for medium production series. It is known for its lightweight and excellent thermal conductivity, which enables fast cooling times and thus shortens production cycles. Additionally, aluminum is easy to work with and can create precise molds with smooth surfaces, essential for applications like automotive parts or consumer goods. Another benefit of aluminum is that it is a cost-effective solution compared to steel, especially when the mold’s requirements aren’t too extreme. However, aluminum is less durable than steel and wears out faster with high production volumes.Steel in Mold Making

For molds that need to withstand extreme stresses and high production volumes, steel is the top choice. Steel molds are known for their durability, hardness, and resistance. They can withstand significant mechanical loads and high temperatures, making them ideal for mass production. Steel molds are commonly used in industries such as automotive and medical technology, where absolute precision and long service life are essential. However, since steel is heavier and more challenging to work with, the cost of producing steel molds is higher, and production time can be longer. Nonetheless, they offer an economical solution for demanding applications in the long run due to their robustness.Material Selection in the Project Context

The choice of the right material depends heavily on the planned production quantity, application type, and cost requirements. For prototypes or small series where quick results are needed, plastic is often sufficient. For medium series or projects requiring good thermal conductivity and lower material costs, aluminum is an excellent choice. Steel is best for high volumes and applications where the mold is subject to extreme loads.MODELLTECHNIK offers a wide range of solutions by flexibly utilizing these materials for their clients. With years of experience and the use of the latest manufacturing technologies,MODELLTECHNIK can precisely determine which material best suits each project—always considering cost, efficiency, and quality.

- 5. What Makes Mold Making at MODELLTECHNIK so efficient?

MMODELLTECHNIK combines years of experience, state-of-the-art technology, and a comprehensive range of services to make mold making highly efficient. The process begins with intensive technical consulting to ensure a complete understanding of customer requirements. This is followed by component design using CAD software, supported by mold flow and warpage simulations to optimize production.

Tailored Tools for Different Requirements

For varying production needs, MODELLTECHNIK offers both prototype tools and small-series tools . These allow functional prototypes to be tested and adjusted in the early stages before moving to series production. The prototype tools offer flexibility and speed, while small-series tools are efficiently used for medium-sized productions. These tools ensure the highest precision, enabling customers to bring their products to market in the shortest time possible.Blow Molding Tools and Injection Molding Technology

MODELLTECHNIK is also a leader in manufacturing blow molding tools , used for producing hollow bodies like bottles or technical components. These tools enable complex geometries and high-quality surfaces. With its in-house injection molding technology , developed molds and tools can be directly tested to ensure optimal functionality. This significantly shortens development time and allows for early identification of potential improvements.Finishing and Final Processing

MODELLTECHNIK places great importance on the surface finishing of the manufactured molds and tools. Finishing not only enhances the appearance of the parts but also increases their resistance and durability. Surfaces such as polished, matte, or coated provide customers with various options to customize their products and meet specific requirements.The seamless integration of technical expertise, modern manufacturing technologies, and personalized consulting makes mold making at ModellTechnik highly efficient. Customers benefit from tailored solutions that are both economically and technically advantageous, fully meeting the demands of modern production processes.

- 6. Application Areas: Where Is Mold Making Used?

Mold Making is Essential in Various Industries

MODELLTECHNIK provides cross-industry solutions for producing high-precision tools and molds used in various sectors:

Automotive Industry

In the automotive sector, molds are used to manufacture parts like dashboards, door panels, and bumpers. Here, it is crucial that molds meet high standards of dimensional accuracy and surface quality.Medical Technology

For the production of medical devices and prosthetics, precision and hygiene are essential. MODELLTECHNIK manufactures molds that meet the strict requirements of the medical technology field.Aerospace Industry

The aerospace industry requires extreme accuracy and lightweight construction for component production. MODELLTECHNIK produces specialized molds for sensors and other highly complex components.Design and Consumer Goods

In design and lifestyle, MODELLTECHNIK offers innovative solutions for manufacturing creative patterns, casings, and coverings. Surface finishing is also key here to meet both aesthetic and functional requirements.Learn more about specific case studies and see how MODELLTECHNIK has realized challenging projects: MODELLTECHNIK Case Studies.

- 7. The future of mold making: new materials and technologies.

Mold making is constantly evolving, and new technologies and materials play a key role in this. At MODELLTECHNIK, the focus is on the use of innovative production methods such as additive manufacturing. 3D printing and new material combinations make it possible to produce more complex molds faster and more cost-effectively.

Smart manufacturing technologies and the automation of production processes are also shaping the future of mold making.

Sustainability and resource-saving materials

The future of mold making will also be strongly influenced by the development of sustainable materials. Companies are increasingly turning to environmentally friendly alternatives to traditional materials in order to achieve both ecological and economic goals. Lightweight construction and the use of recyclable materials play a crucial role here, particularly in the automotive and aviation industries, where weight and material consumption are closely linked to the efficiency and environmental friendliness of products.

Digitalization and automation

Advancing digitalization is fundamentally changing mould making.The use of automated production and smart control systems makes it possible to manufacture molds with greater precision and speed.These technologies make it possible to detect production errors at an early stage, make adjustments in real time and make the entire production process more efficient.

Conclusion on the future of mold making

With these developments, mold making is facing an exciting future. The combination of new materials, smart manufacturing technology and sustainable processes offers enormous opportunities for optimizing production.MODELLTECHNIK is already focusing on these trends and technologies in order to remain a pioneer in modern mold making and offer its customers tailor-made, future-proof solutions.

Would you like to make your production more efficient and future-proof? MODELLTECHNIK offers you comprehensive solutions in mold making - from technical advice and component design to tailor-made tools for small series and prototypes. Thanks to state-of-the-art technologies such as Moldflow simulations, injection molding pilot plant and surface finishing, we guarantee maximum precision and quality. Rely on innovation and experience for your projects. Use our contact form now and find out how we can best implement your requirements.

Our case studies

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„I wanted to thank you again for the quick “just-in-time” production of our two models. [...] The pieces look impressive and will certainly serve their purpose!“

„I wanted to thank you again for the quick “just-in-time” production of our two models. [...] The pieces look impressive and will certainly serve their purpose!“