Prototype Tools

The bridge to series production.

Prototype tools are the key to producing components quickly, precisely, and cost-effectively in small series – especially in plastic injection molding. They make it possible to test complex geometries under real conditions before investing in an expensive series tool. As a specialized manufacturer of prototype tools with a focus on small series and plastics processing, MODELLTECHNIK offers precise solutions.

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

What Are Prototype Tools?

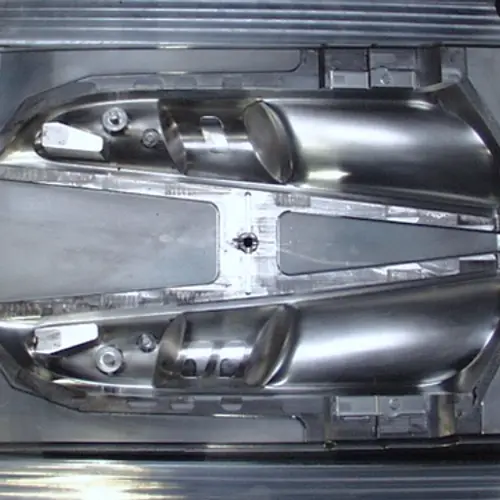

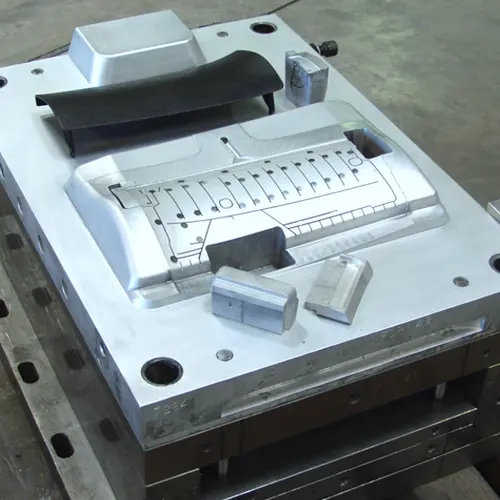

Prototype tools are specially designed injection molds, usually made from aluminum or steel, and are used for the production of sample parts or small series. They provide the basis for testing components under realistic conditions – functionally, mechanically, and visually. This delivers crucial insights for design, material selection, and subsequent series production.

Where are prototype tools used?

In contrast to conventional series tools, which are designed for high volumes and maximum durability, prototype tools focus on fast availability, flexibility, and cost control. This makes them ideal for development phases, small series, or pre-production runs where modifications are still expected.

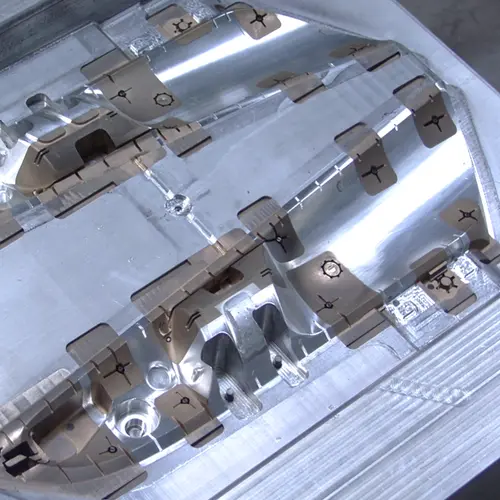

Especially in the field of prototype tools for plastics, the injection molding process plays a key role. It enables the production of near-series parts already in early project phases – using the same plastics, tolerances, and requirements as later in the production process. As a result, such tools are suitable not only for internal testing but also for customer samples, installation space trials, or functional small series.

What are the differences compared to production tools?

The most important difference between a prototype tool and a series tool lies in the production objective. While a series tool is designed for maximum service life, optimized cycle times, and millions of shots, a prototype tool aims to produce functional plastic parts quickly and cost-effectively in small quantities – often ranging from 10 to 1,000 units.

Material selection and design effort differ significantly. Series tools are typically made of hardened steel and equipped with complex slide mechanisms, cooling channels, and automated demolding systems. Such constructions are both costly and time-intensive – and often not economical when the product design is still uncertain.

Prototype tools, such as those manufactured by ModellTechnik, are usually made from aluminum or unhardened steel. They can be produced more simply, modularly, and quickly – often within just a few weeks. Through targeted simplifications, such as manually demolding undercuts using inserts, even complex geometries can be realized without incurring high tooling costs.

This makes the use of prototype tools in plastic injection molding an ideal solution for developers, designers, and project managers who need near-series components without yet investing in a final series tool.

Prototype Tools at a glance.

Speed

Balancing technical functionality and cost efficiency, e.g., via lean, adaptable design.

Cost optimization

Through modular master molds, manual demolding techniques, and reduced tool complexity, customers can save significant costs.

Production material

Whether PP, PA, ABS, or advanced engineering plastics – they can be processed in prototype tools under nearly the same conditions as in series tools.

Flexibility

Since prototype tools are modular in design and, in many cases, made from aluminum, modifications to the component can be implemented with manageable effort. For projects in the validation or optimization phase, this is an invaluable advantage.

Our case studies

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„I wanted to thank you again for the quick “just-in-time” production of our two models. [...] The pieces look impressive and will certainly serve their purpose!“

„I wanted to thank you again for the quick “just-in-time” production of our two models. [...] The pieces look impressive and will certainly serve their purpose!“