FINISHING

THE PERFECT FINISH FOR YOUR PRODUCTS

Our assembly departments complete the finishing work on prototype, pre-series and small-series parts, treat the surfaces, adjust them with various additional parts and finally assemble them into functioning modules. We offer a broad range of different finishing and marking methods to give the components high-quality surface finishes as requested by our customers.

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Our finishing services

PROTOTYPING CAN LOOK THIS GOOD

Alongside lamination, painting, flocking and metallising, there are countless other processes to choose from. Speak to us about vibratory finishing, chemical smoothing, matt finishes, anodising, burnishing or nickel plating. We have the right expertise for every type of finishing – either in-house or through close collaboration with experienced partners

LAMINATION

Innovative lamination processes for the highest design requirements.

Lamination gives a visual upgrade to plastics or components made of natural fibres and gives them a perfect look and feel. Your products gain their own individual character with hand and press lamination.

Leather-laminated door panel with contrasting decorative stitching and chrome-plated handle.

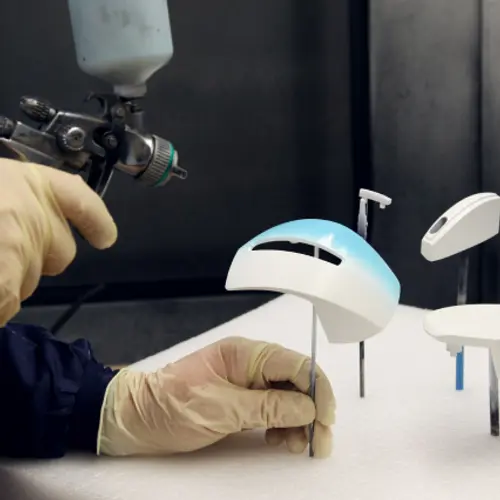

PAINTING

Filling and painting – the perfect surface for your product.

Filling and painting are two important steps in surface preparation and finishing. Careful and precise use of these techniques is essential. Our experts possess the latest expertise and work with two state-of-the-art painting chambers to guarantee top quality finishing for your products.

Individual painting of prototypes.

FLOCKING

The velvety finish for high-quality products.

Flocking upgrades the appearance of your products. It can be the ideal solution in all areas where you’re looking to enhance the look and feel.

Flocked door for glove compartment.

METALLISING

For products with metallic shine.

Metallising of plastics is an innovative coating technique that combines decorative and functional properties. Shiny, mirror-like surfaces that have been metallised offer higher scratch resistance and durability, for example.

Matt and shiny surface finish.

Our case studies

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“

„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“