MODEL MAKING

IDEAS TAKING SHAPE

Our model making service transforms your product ideas, designs and concepts into reality for the first time. Our experts will advise you on materials and technologies. Our broad range of technology means that there are no limits to the size, dimensions, look and feel of your ideas.

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Our model making services

INNOVATIVE IDEAS, PROFESSIONAL EXECUTION.

Whether it’s a functional prototype or sample part, we set benchmarks with our modern machinery and varied technologies – always with a focus on speeding up and improving your product development process.

MILLING

Precise and efficient for a wide range of materials.

With the help of state-of-the-art 5-axis milling machines, we can produce free-form shapes up to a length of 5 m with outstanding surface quality and accurate dimensions and geometries. This increases the efficiency of machining and also significantly speeds up subsequent processes.

Our Zimmermann FZ 33 is ideal for machining aluminium and composite materials. These varied options mean that the portal milling machine is used for prototyping, design model making and boat building. It is also used for models, cubing, jigs and gauges.

The Zimmermann FZ 33 in use.

LOW-PRESSURE INJECTION MOULDING (RIM)

For large moulded plastic parts in top quality.

We offer two processes here for producing large-format and complex plastic components in high quantities: the low-pressure RIM process and the high-pressure RIM process.

Both enable efficient production of large-format and complex plastic components with a wide range of materials for huge variety of applications.

Inserting 2K polyurethane resin into a Ureol mould.

LAMINATION (CFRP, GF, VACUUM INF.)

Expertise in every layer.

Laminating is used to produce composite materials by impregnating various layers of material with resin. The advantages of this method include high corrosion resistance, low tooling costs, and excellent mechanical properties combined with low weight. At MODELLTECHNIK, we use hand lay-up and vacuum infusion laminating processes.

CFRP vacuum infusion laminate side wall.

Thermoforming

Unique thermoformed parts – quickly and efficiently.

If you want to produce moulded parts with large dimensions in small to medium quantities, thermoforming is the process you need. The comparatively low tool costs and the short throughput times make this process highly cost-effective. The low weight of the formed parts also has a positive impact on the production time.

Thermoforming tool for the side panel of a BMW electric scooter.

MODULE ASSEMBLY

The perfect combination for every product.

In module assembly, all prefabricated individual parts and components are put together to produce the final product. Producing assembly aids and jigs in-house means that we can quickly and efficiently meet even extremely complex requirements.

Module for use in automated lab diagnostics.

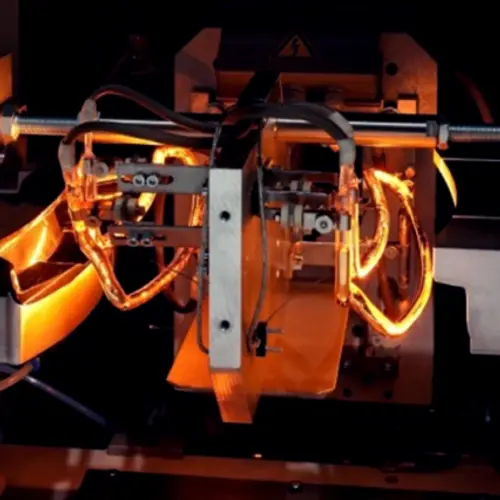

PLASTIC WELDING

Modern joining processes for plastics.

We offer various welding processes that can be used according to the geometry, material and application area of the product. The portfolio of technologies ranges from ultrasound welding and vibration welding to infrared welding to mirror welding.

Prototype welding tool with 3D contoured tube emitters.

FOAMING

Light. Strong. Innovative. Plastic foams for every application.

We produce samples and small series with polyurethane foams by hand or with casting machines. Rear foaming enables visual and haptic production of functional prototypes. Our strengths lie in innovative projects with functional integration, such as embedding heating elements.

Cross-section of an armrest – foam-filled with PVC skin.

Our case studies

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“

„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“