MEASUREMENT TECHNOLOGY

The latest measurement technology for perfect results.

Continuous measurements during production allow deviations to be detected in real time. This makes it possible to take corrective action immediately and thus reduce rejects. Thanks to state-of-the-art measurement technology, we guarantee our customers compliance with standards and consistently high quality.

Metrology in Practice

Measurement technology at its best

Our measuring systems integrate advanced measuring technology and deliver extremely accurate measurement data, which is essential for maintaining tight tolerances in production.

MEASUREMENT TECHNOLOGY

Precision in every step - our machinery makes the difference.

From modern software and coordinate measuring machines to balancing machines for impellers and moisture meters. MODELLTECHNIK offers its customers a modern machine park to ensure maximum precision and accuracy at all times.

Quality Management

Machinery

Download

Coordinate measuring machine with Premium accuracy class.

Inspection Processes in Additive Manufacturing

In processes such as SLS or SLA, deviations can occur due to material shrinkage, layer buildup, or temperature variations. To ensure you still achieve the desired quality, we rely on state-of-the-art metrology.

This helps you save time, avoid costly rework, and receive parts that perfectly match your requirements – right from the early development phase.

Advantages

Guaranteeing dimensional accuracy and surface quality

Detecting distortions and errors at an early stage

Providing transparent documentation and CAD data comparison

From prototype to series part: quality you can hold on to.

Quality control in subtractive processes

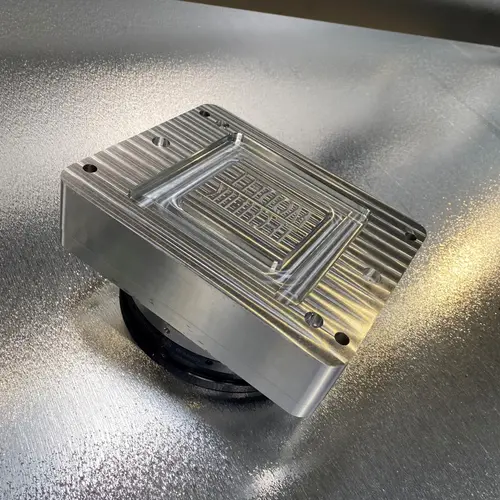

Metrology is essential in milling and injection molding. It ensures that parts meet design specifications, tolerances are maintained, and tools operate with precision. Deviations are detected early, avoiding costly rework.

In milling, coordinate measuring machines and spindle probes capture even complex geometries with high accuracy. In injection molding, metrology guarantees that molds close precisely and parts can be demolded without defects.

Advantages

Reduced scrap

Stable processes

Consistently high quality

Injection molding tool ready for measurement

Coordinate Measuring Technology and Advanced Sensorics

For maximum accuracy, we rely, among other things, on the LH1512 coordinate measuring machine equipped with advanced sensor technology. This allows us to reliably measure even complex geometries and large components. Dimensional accuracy as well as form and positional tolerances are recorded precisely and compared with the CAD data.

In this way, we ensure that our prototypes and series parts not only meet the required quality standards, but also achieve them consistently with reproducible precision.

Our case studies

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„The lifeblood of MODELLTECHNIK is in every prototype. You can feel that in the collaboration and in the results.“

„The lifeblood of MODELLTECHNIK is in every prototype. You can feel that in the collaboration and in the results.“