Selective

Absorption Fusion

Precision meets speed in additive manufacturing

Selective Absorption Fusion (SAF) is a groundbreaking technology that elevates additive manufacturing to the next level. By utilizing targeted heat application and advanced material processing, SAF enables the rapid, precise, and cost-effective production of high-quality plastic parts. Whether for serial production or functional prototyping, SAF delivers consistent results with exceptional detail accuracy and uniform material properties.

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Revolutionizing Additive Manufacturing.

An introduction to the manufacturing proces

Selective Absorption Fusion (SAF) is an advanced technology used in additive manufacturing (3D printing). It is particularly known as a powder-based process that shares similarities with Multi-Jet Fusion (MJF) and Selective Laser Sintering (SLS), but utilizes its own unique method for melting and fusing the material.

THE COURSE OF THE PROCEDURE

1. POWDER COATING

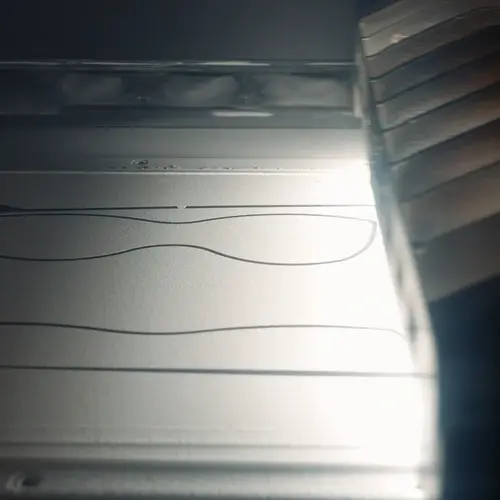

First, a thin layer of plastic powder is evenly distributed across the print platform. A specialized powder management system ensures uniform distribution to maintain high print quality.

Powder layer in the Stratasys H350

2. Selective absorption and fusion

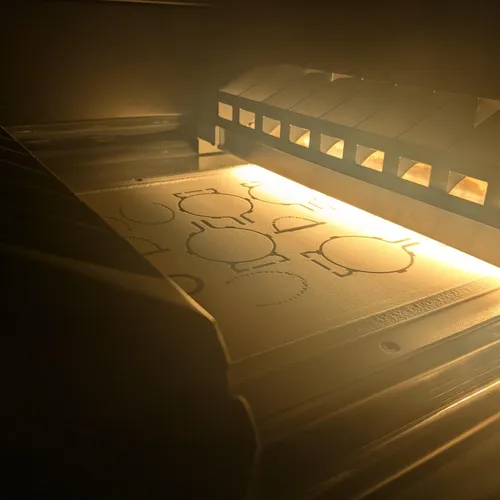

A liquid, known as a high-absorbing fluid, is then selectively applied to the areas of the powder layer that will later be fused together using an industrial print head. This fluid acts as a heat absorber and enables targeted energy absorption during the subsequent heating process.

Once the fluid has been applied, an infrared heat source is used. This heats the entire powder layer evenly, but only the areas treated with the absorption fluid absorb sufficient heat to fuse together. The remaining powder particles remain unchanged and serve as support material for the subsequent layers.

Fused structures after the application of the High-Absorbing Fluid

3. Cooling & Post-Processing

Once a layer has been successfully fused, a new layer of powder is applied, and the process repeats. This layer-by-layer buildup continues until the entire part is completed. After the printing process is finished, the part must first cool down within the powder bed to prevent material stress and ensure high dimensional accuracy. The excess powder is then removed using compressed air and glass beads. Depending on the requirements of the final product, additional post-processing steps may follow, such as dyeing or surface coating, to enhance both the appearance and functionality of the part.

Cleaning of the components

What distinguishes SAF from other 3D printing processes?

Unlike processes such as Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF), SAF uses a specialized absorber fluid that is selectively applied to powder layers. A heat source activates the fluid, causing the powder to fuse layer by layer. This enables precise manufacturing with consistent mechanical properties in all directions (isotropic material properties) – a key advantage for functional prototypes and small-batch production.

Diversity in 3D Printing

SAF IN PICTURES

Advantages of SAF for Prototypes and Small-Series Production

Advantages of SAF for Prototypes and Small-Series Production The Selective Absorption Fusion (SAF) process offers a range of advantages that make it particularly attractive for prototyping and small-series manufacturing. Thanks to its high efficiency, precise layer processing, and excellent mechanical properties, SAF enables the cost-effective production of functional plastic components with high repeatability.

- High Part Strength and Isotropic Material Properties

One of the key advantages of SAF is the uniform mechanical strength of printed parts in all three spatial directions (X, Y, and Z).

In many additive manufacturing processes, particularly Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM), parts often exhibitlower strength in the Z-direction due to weaker bonding between successive layers compared to within a single layer.

SAF overcomes this issue through two main factors:

- Large-area heat transfer: The infrared heating system ensures even material fusion across the entire layer.

- Efficient powder distribution: The mechanical roller compacts the powder, creating uniform layers with high packing density, which contributes to a homogeneous material structure.

The result is robust and durable parts, making SAF ideal for mechanical function tests and real-world applications.

- Low Unit Costs for Medium Production Volumes

For companies requiring small-series or pre-series production, cost efficiency is a crucial factor. SAF offers particularly low unit costs when medium production volumes are needed.

This is due to several process-related advantages:

- High packing density in the build chamber: SAF allows for highly efficient use of build volume, as parts can be densely stacked.

- Fast processing times: The simultaneous heat application across the entire layer makes the process faster than SLS, where a laser scans the material point by point.

- Powder reusability: Unused powder can be recycled for future prints, minimizing material waste.

These characteristics make SAF the ideal choice for the cost-effective production of plastic components in quantities ranging from a few dozen to several hundred units.

- Efficient Material Utilization and Sustainability

Additive manufacturing technologies offer a significant ecological advantage over subtractive processes such as CNC milling or injection molding, as they generate less waste.

SAF further optimizes material usage through:

- Minimal material loss: Since unsintered powder can be reused after the printing process, almost no waste is generated.

- Precise layer deposition technology: The roller-based powder application ensures that only the necessary amount of material is used.

- Energy efficiency: The uniform infrared heating system reduces energy consumption compared to high-power laser-based processes.

As a result, SAF enables a resource-efficient manufacturing process, reducing both material consumption and operating costs.

- Scalability and repeatability

Another key advantage of SAF is its scalability. Since the process operates independently of part complexity, both simple and highly intricate geometries can be manufactured with consistent quality.

Additionally, SAF offers high repeatability, ensuring that multiple production batchesmaintain the same material properties and dimensional tolerances. This characteristic is crucial for industries such as aerospace, automotive, and mechanical engineering, where precise reproducibility of components is essential.