Lamination

Maximum durability and design freedom.

In a world in which innovation cycles are becoming ever shorter and product developments increasingly complex, the selection of suitable manufacturing processes is gaining in importance - especially in prototype construction. Laminating is one of these processes, which is characterized by a high degree of design freedom, stability and lightweight construction potential.

MODELLTECHNIK create customized solutions for a wide range of industries. Thanks to many years of experience, state-of-the-artmachinery and precise manual work, ModellTechnik produces fiber-reinforced components that set standards in terms of quality and function.

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Our model making services

Lightweight construction meets precision

For companies that want to implement complex components with functional and aesthetic requirements, lamination offers a convincing solution - especially when additive or conventional processes such as injection molding reach their limits. Laminating is a flexible approach that efficiently combines design and technical requirements, especially for one-offs and small series.

GRP

Glass fiber reinforced plastic

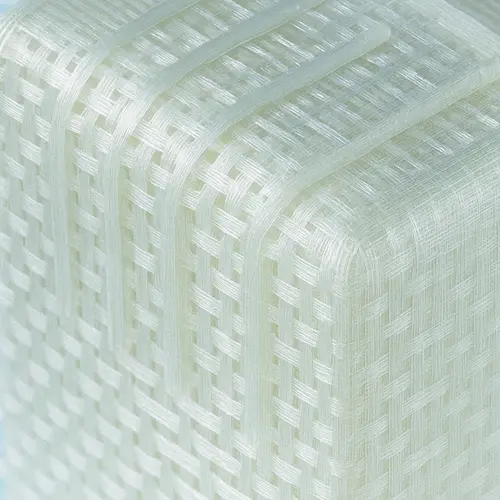

GRP is the most widely used composite material in the lamination process. It consists of glass fiber mats or fabrics that are impregnated with a resin system (usually epoxy or polyester resin) and then cured. GRP offers a goodstrength-to-weight ratio, is inexpensive and relatively easy to process.

Good mechanical strength

High chemical resistance

Electrically insulating

Less expensive than CFRP

Slightly higher density than CFRP, therefore heavier

Close-up of a cube made of fiberglass laminate

CFRP

carbon fiber reinforced plastic

CFRP is the premium solution in the field of fiber composites. The use of carbon fibers creates an extremely rigid, but at the same time very light compositematerial. CFRP isusedwherever maximum performancewithminimumweightisrequired.

Outstanding rigidity and strength

Very low weight

Very low thermal expansion

Electrically conductive

Higher material and processing costs

Body part made of carbon fiber reinforced plastic

Resin Infusion Process

Vacuum infusion

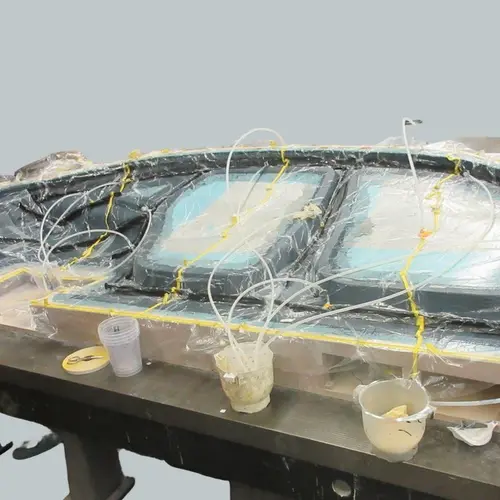

Vacuum infusion, also known as the Resin Infusion Process or VARTM (Vacuum Assisted Resin Transfer Molding), is a modern manufacturing method for producing lightweight yet highly durable fiber-reinforced composite parts made of fiberglass or carbon fiber. In this process, dry fiber layers are placed into a mold, sealed airtight with a vacuum bag, and then infused with low-viscosity resin under vacuum pressure. The controlled resin flow ensures parts with a very high fiber content, low porosity, and excellent mechanical properties.

This method offers efficiency, dimensional accuracy, and environmental benefits, as the closed process significantly reduces emissions. Typical applications include boat building, wind energy, automotive and aerospace industries, as well as prototype manufacturing, where maximum quality and weight reduction are essential.

Vacuum infusion of a complete car body side with carbon fiber laminate

Advantages of laminating in prototype construction

High design freedom

Free shaping even with complex geometries, free-form surfaces and organic contours

Lightweight construction with high strength

Use of GFRP and CFRP enables stable yet lightweight components

Cost efficiency for small series

No expensive tools required, low initial costs

Fast implementation

Reduces time-to-market and enables iterative testing and optimization

High surface quality

Suitable for presentation models, functional models or design-relevant components

Variety of materials & adaptability

Combination of different fiber types and resin systems for specific properties

Combinability with other processes

Integration with 3D printing, vacuum casting or CNC-manufactured inserts possible

Our case studies

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“

„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“