SERVICES

STEP BY STEP TO THE PERFECT RESULT

Our experts perform each individual step in gauge construction with the greatest care and precision to guarantee you the best possible quality. We offer you personal and comprehensive advice – from the specifications for your enquiry through to validation – and make sure that any questions are answered. Just get in touch!

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Maximum data protection

Your data is in safe hands with us

35 years of experience

Resilient prototypes for your projects

Efficiency

Combination of versatility and material diversity

For every industry

From automotive to dentistry

Well advised

Reach your goal quickly with our experts

Our gauge construction services

THE MEASURE OF QUALITY AND PRECISION.

From the initial consultation to the product specification and measurement – we have the best experts to support you along the way to the perfect solution for your needs.

CONSULTATION

The beginning of an optimum end result.

When it comes to gauge construction, it is crucial to develop accurate and reliable measurement instruments to ensure the quality and precision of your production. We implement all of your requirements and those specified by your customers when designing and producing your testing equipment.

Consultation – helpful, friendly and efficient.

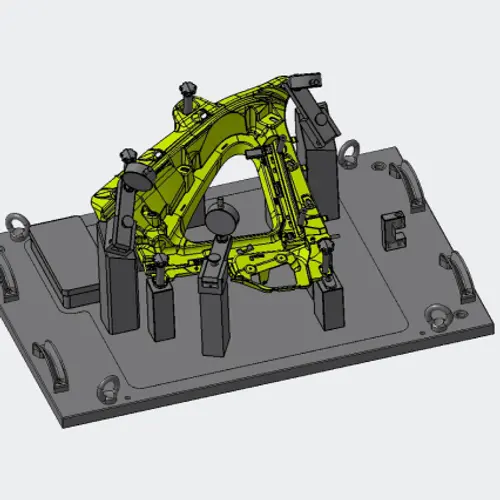

DESIGN

The foundations for perfect implementation.

The gauge design process follows the applicable requirements specification, component drawing and the component data provided by the customer. We place great value on direct communication with our customers.

Creating a 3D concept in CATIA.

PRODUCTION

A focus on meticulous workmanship.

We manufacture all the components for the testing equipment in-house in our modern milling centre. Customers benefit in particular from the internal knowledge of production processes such as stereolithography, selective laser sintering or 3D printing to reduce the weight of individual components.

Assembling a vertical tensioner.

MEASUREMENT

The highest degree of measurement expertise.

Our company’s VDA, DIN EN ISO 9001:2015 and IATF 16949:2016 certifications guarantee our high quality standards. The very latest measurement and testing methods are used across all stages of product development to ensure excellent precision during production.

Calibrating an RPS system.

VALIDATION

For lasting quality.

To test the repeat accuracy when inserting the test component in the gauge, we perform validation – i.e. check the measurement equipment capability – in procedure 1 or 2 according to customer requirements. For every gauge, you’ll receive all the documentation you need to operate the gauge. If you still have questions after reading the documentation, our experts will be happy to help at any time.

Measurement process with digital meter for measurement system analysis.

Our case studies

Automotive

A body with class: We produced the master model for the body of the cult Evetta light electric vehicle on a 1:1 scale – with perfect milling and the finest surface finishing. Find out how.

Industry

The socket for the forest: We developed the prototypes for a type of powerbank for Stihl, which was put through its paces by forestry workers. A truly powerful project.

Aerospace

"Jena, we have no problem": Jena-Optronik commissioned MODELLTECHNIK to produce a 1:1 model of the Gateway Docking Port, which is needed for sensor tests in space applications.

Design

Timeless and dignified: Working with Samosa and our expertise in 3D printing, MODELLTECHNIK creates beautiful templates and design samples for individually designed funeral urns.

Contact us

Whether you’ve got technical, commercial or specialist questions – we’re here to help.

START A QUERY NOW„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“

„Spot-on delivery under extreme time pressure [...] It couldn't be more perfect“